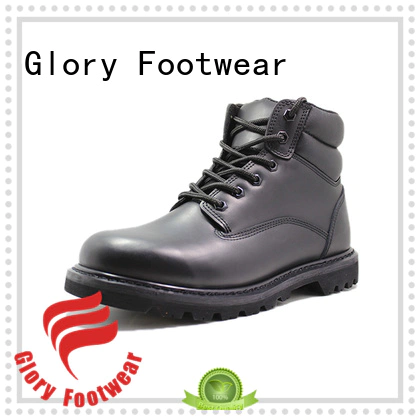

Genuine leather Goodyear welted shoes ,this is a shoe made by Goodyear welted stitching process. The upper, midsole and seam are stitched together by hand, and then the outsole is attached. Goodyear welt structure is the world's top unique handmade shoe technology. Goodyear handmade shoes need to be completed through multiple processes in the production process, each of which requires elaborate production by experienced and skilled shoemakers. Most of the top shoes are made with Goodyear craftsmanship and use natural high-quality full cowhide material, so Goodyear handmade shoes are made of high-quality materials in order to reflect the distinguished status of the wearer.

Features:

Sole: shock-absorbing, oil-resistant, non-slip rubber outsole.

Heel: According to the ergonomic design, the heel support is stable, and you will not feel tired after working for long hours and walking with this shoe.

Tongue: Made of genuine leather and padded foam, light and comfortable.

Qingdao Glory footwear Co., Ltd. is a professional safety shoes manufacturer, our associate factory with experience for over twenty years, located in Gaomi, Weifang City, Shandong Province, with convenient transportation access. We are mainly producing safety shoes for labor, army boots, police boots & military boots, as well as hospital and kitchen working shoes. There are different series of safety products to meet different requirements. we have PU injection lines and cement production line, the annual output of more than 4,000,000 pairs of shoes. We have been authorized by CE EN 20345 standards. Our products have been sold well all over the world, including North America, South America, Europe, Africa, Middle East, South Asia, Southeast Asia, more than 20 countries and regions. Our real safe shoes protect your business, caring for world - wide workers! Our goal is "Best quality, Best delivery, Best price and Best services". Client is first, dedicated to strict quality control, and thoughtful customer service, experienced staff members are always available to discuss your requirements and ensure customers satisfaction. We also welcome OEM and ODM orders, and welcome customers from all over the world to establish business relationship with us!

The advantage of Goodyear's edge strip technology is that the upper and sole are firmly connected, which can withstand impact and twisting. A layer of cork is laid between the midsole and the outsole to ensure maximum breathable of the leather shoes. Regarding Goodyear welt shoes, we have other more styles for you to choose. If you are interested in our products, you can visit our website or contact us for learning about more information.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved